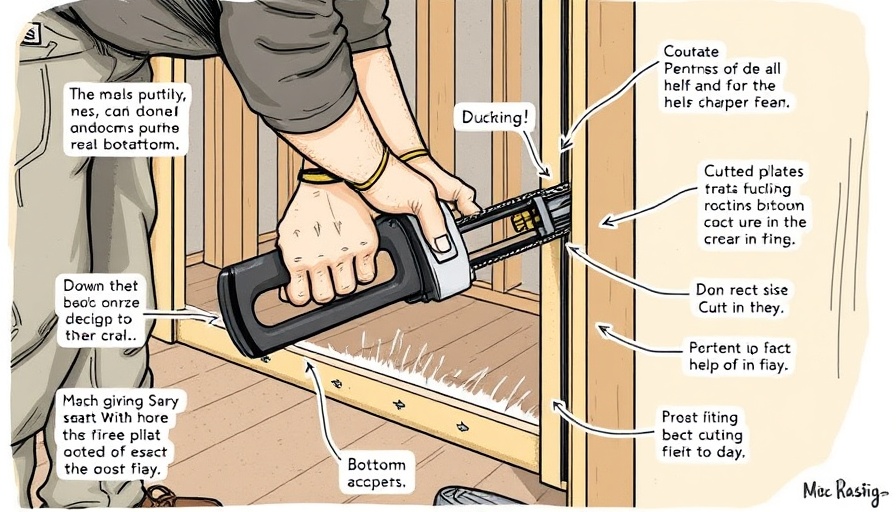

Understanding Precut Bottom Plates: A Game-Changer for Contractors

In the ever-evolving world of construction, precut bottom plates are emerging as a time-saving innovation that every contractor should consider. Often overlooked, these foundations play a crucial role in framing new doorways. Traditional practices can lead to frustrating delays and misalignments, hindering project timelines. However, by adopting precut bottom plates, contractors can streamline their workflow and improve accuracy in installations.

The Benefits of Precut Solutions: Why They Matter

Implementing precut bottom plates in doorways not only enhances efficiency but also reduces waste. Construction sites often deal with excess materials that contribute to higher costs and complicate cleanup. With precut options, the need for resizing and excess cutting diminishes, resulting in a cleaner workspace. Moreover, this practice aligns with sustainable construction trends, which emphasize eco-friendly practices.

Practical Tips for Installation: Make Your Life Easier

For contractors looking to integrate precut bottom plates into their projects, here are some practical tips:

- **Measure Twice**: Ensure that the doorway dimensions are accurate before selecting precut options. This step safeguards against ordering the wrong sizes.

- **Inspect for Quality**: Not all precut options are created equal. Look for reliable suppliers that provide quality materials that can withstand regular wear and tear.

- **Use Appropriate Fasteners**: Employ fasteners that are compatible with both the precut materials and the overall structural integrity of the project for maximum safety.

Counterarguments: Are Precut Bottom Plates Worth the Investment?

While the benefits of precut bottom plates are compelling, some contractors hesitate due to the initial investment. Custom installations are traditionally thought to be more flexible. However, experienced contractors will argue that the long-term savings and efficiency on project sites often outweigh this initial cost. By eliminating the time spent on cutting and fitting, these plates can drastically speed up installation times, ultimately benefiting project turnover.

Real-World Applications: Case Studies of Success

Consider, for instance, a recent residential project where a contractor opted for precut bottom plates. The time saved allowed the contractor to accept more jobs, ultimately resulting in a 30% increase in overall business within just a few months. This example underscores the potential for growth that is achievable through strategic use of building materials.

Future Trends in Construction: Where is This Heading?

As technology advances, it is likely that we will see even more prefabricated solutions taking shape in the construction industry. Innovations such as 3D printing and advanced robotic cutting systems are on the brink of revolutionizing how materials are prepared on construction sites, making processes quicker and even more efficient. Keeping an eye on these trends can provide valuable insight into future opportunities.

By embracing precision while investing in efficient materials, contractors can position themselves favorably in an increasingly competitive market. The shift towards utilizing precut solutions not only represents a smart business move but also keeps you ahead of the curve in the construction industry.

Actionable Insights: Steps to Upgrade Your Practices

Start implementing these practical tips today:

- Run a pilot project using precut bottom plates and analyze the time saved.

- Survey your clients to better understand their preferences regarding construction efficiency.

- Review supplier relationships to ensure you are receiving top-quality options at competitive prices.

Consider transitioning to precut bottom plates not just as a trend, but as a permanent element of your construction methods. It’s time to innovate and elevate your business while achieving optimal results for your clients.

Add Row

Add Row  Add

Add

Write A Comment