Transforming Infrastructure: Louisiana's Innovative Subsurface Data Tool

The Louisiana Department of Transportation and Development (DOTD) is breaking new ground with its recent adoption of a state-of-the-art subsurface data management tool: OpenGround. This transformative technology aims to enhance the resilience and efficiency of transportation infrastructure throughout Louisiana. By migrating geotechnical data from over 2,500 projects into a centralized cloud system, DOTD not only streamlines access to crucial information but also positions itself among the forefront of transportation innovation.

A Data-Driven Future for Transportation

With the U.S. Department of Transportation committing $146.2 billion towards infrastructure investments for 2025, Louisiana's initiative reflects a broader trend towards data-driven solutions in the civil engineering sector. "Data is an asset, has value, and should be managed properly," states Gavin Gautreau, Senior Geotechnical Research Engineer at the Louisiana Transportation Research Center (LTRC). This mindset is pivotal as the state grapples with unique environmental challenges, including high rainfall and subsidence, necessitating a more analytical approach to infrastructure management.

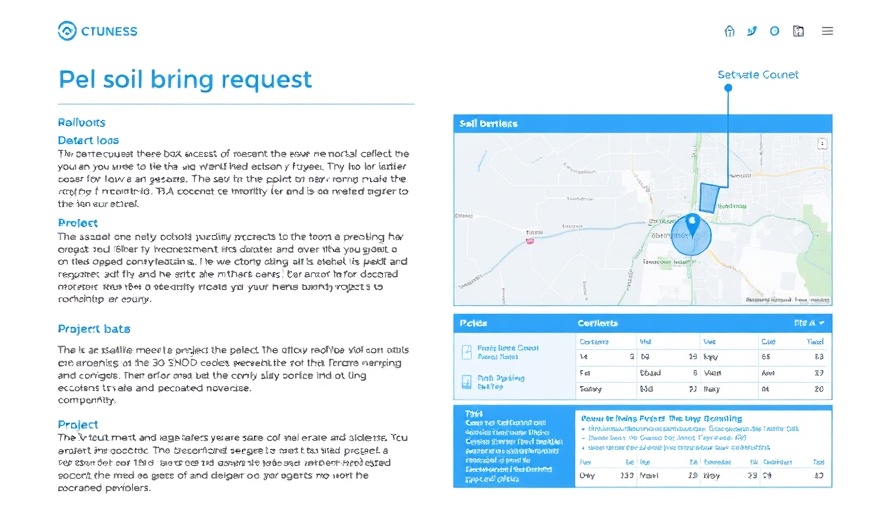

The Importance of Geotechnical Data Management

Previously, the process of conducting soil investigations and managing data was encumbered by traditional paper logs and manual data entry. As Assistant Geotechnical Engineer Administrator Jesse G. Rauser puts it, "We needed long-term insight into Louisiana’s soil conditions." The costs associated with soil borings can skyrocket, sometimes reaching $15,000 each, thus preserving and capitalizing on existing data becomes invaluable. The transition to OpenGround promises not only time savings but also substantial cost reductions for Louisiana taxpayers.

Experiencing Efficiency Through Digital Transformation

The implementation of OpenGround has introduced multiple efficiencies into DOTD’s operations. For example, calculations and visualizations can now be generated within minutes, reducing the typical project turnaround significantly. Rauser notes, "The tools we’ve built to visualize data save at least an hour per project," emphasizing the drastic impact on workflow efficiency. This focus on reducing unnecessary manual processes directly enhances the effectiveness of project planning, allowing for quicker, data-driven decision-making.

Technological Innovations and Collaboration

Beyond simple data storage, OpenGround allows for innovative features such as automated analysis and real-time collaboration across multiple engineering teams. With cloud capabilities, sharing information between different DOT offices and partner consultants becomes seamless, positioning Louisiana to set a benchmark for states looking to modernize similar processes. This collaboration is further highlighted by advancements in drone technology. The increased accessibility of high-quality data plays an essential role in both planning and executing infrastructure improvements and expansions.

Facing Challenges Head-On

Transitioning to a digital-first approach is not without its challenges. Resistance from staff accustomed to traditional methods was initially prevalent. However, recognition of the long-term benefits of data accessibility is gradually winning over engineers previously reluctant to embrace change. Building confidence in the permanence of cloud-based data management will remain a priority, ensuring that people understand the potent value in moving away from paper logs.

Looking Ahead: Future Insights and Opportunities

The successful deployment of OpenGround demonstrates the potential for sustained improvements in Louisiana’s infrastructure management. As more data becomes available and processes streamlined, DOTD can focus not just on current projects but also on long-term strategic planning. This positions Louisiana to adapt to future challenges more effectively, opening doors to enhancements not just in transportation, but across the state’s broader infrastructure landscape.

Empower Your Projects through Insights

Contractors and home service providers stand to gain significantly from understanding and applying these technological advancements. By leveraging tools like OpenGround, professionals in the field can better manage their projects, ensuring they remain competitive in a rapidly evolving environment. Having access to crucial data can lead to better project outcomes and, ultimately, a stronger commitment to the communities served.

For more information on utilizing technology to streamline your operations and enhance your projects, consider exploring how AI solutions can benefit your home service initiatives.

Add Row

Add Row  Add

Add

Write A Comment